Relevant Documents

(186KB)

(186KB)

Background

Microelectromechanical systems (otherwise known as MEMS) have evolved from their roots in lab research to everyday use, as their adoption in commercial and industrial applications grows. As MEMS technology advances, more advanced testing methods are needed in order to characterize the dynamics – such as vibration and displacement – of miniaturized mechanical and electro-mechanical devices.

Requirement

Until recently, in order to measure the vibration and displacement of MEMS, Laser Doppler Vibrometers (LDVs) were successfully employed. However, advancements in the fabrication process have facilitated the production of high-speed systems whose vibration and displacement levels are not supported by the testing capabilities of LDVs, whose measurements are subject to significant error.

A new, alternative technology, enabling the characterization of microstructure dynamics using optical displacement measurement, has been introduced. Optical Displacement Meters (ODMs) are able to detect and measure minute, high-speed vibrations of MEMS devices, involving no physical contact with the object itself.

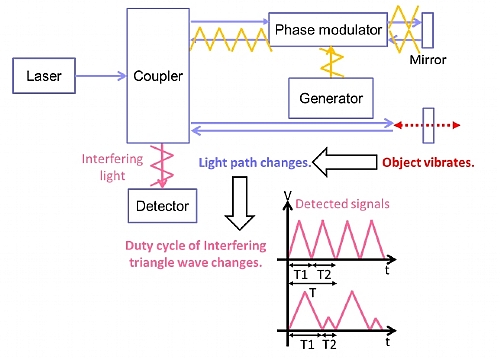

An ODM-based test setup for measuring MEMS displacement appears in Figure 1 below.

Figure 1: Test Setup for ODM Measurement

The system consists of a laser, an optical fiber coupler for dividing and combining the beams, a phase modulator and generator for modulating the beam and an ODM-based detector used to measure the vibration and displacement of the object.

The laser light is divided into a reference light and a signal light. The reference light is then phase-modulated by a triangle wave generated by the generator, and is then reflected back by a mirror. The signal light irradiates the vibrating MEMS object and is reflected back by it.

The reflected signal light and the reference light are then re-combined by the coupler. The resulting interfering light is directed to the ODM detector. Since the reference light is phase-modulated using a triangle wave, the interfering light also assumes the form of a triangle wave.

Vibration of the MEMS device causes changes in the light path, which in turn cause changes in the duty cycle of the triangle wave. The ODM, by observing the changes in the duty cycle of the triangle wave, can measure the vibration and displacement of the MEMS device.

In order to complete the test setup array, a high quality waveform generator is required to provide high-frequency triangle waveforms with excellent linearity.

Solution

Tabor Electronics’ Wave Standard family of high-speed Arbitrary Function Generators (AFGs) provide MEMS developers with an outstanding platform for the testing and measurement of miniaturized electro-mechanical devices.

Wave Standard’s 350 MHz waveform generation frequencies and exceptional linearity are perfectly suited for measurement of the high-speed vibration and displacement characterized by MEMS systems.

When faster modulation frequencies are required, Tabor Electronics’ WaveXciter series of high-speed AFGs provides industry-leading performance, providing triangle waveforms with frequencies of up to 31.25MHz and high-quality linearity.

For More Information

To learn more about Tabor’s solutions or to schedule a demo, please contact your local Tabor representative or email your request to [email protected]